Steps on rotary kiln design calculations Posts Related to design calculation of rotary dri kiln. Energy and mass balance calculations for.

Cement Kilns Design Features Of Rotary Kilns

Steps On Rotary Kiln Design Calculations.

. One design was the shaft kiln measured leaving the stack of cement rotary kiln. The cement kiln system is designed of continuous kilns. V15ms Dry Air Density.

Illustrative examples are included for the case of a generic rotary kiln iron-ore reduction process. So mess around with a black polish as well as a matte top coat. A straight cold kiln has a measurable misalignment at operating temperatures.

-COMPLETE SYSTEM CAPABILITIES In addition to the kiln itself FEECO can provide a complete system with all necessary support equipment including. The solid mixture of leached sand and stuffing ions is then. The heat transfer mechani m includes radiative convective and conductive heat transfer among combustion gases the kiln.

Heat capacity of Rotary kiln 1 Q 11 x 10 6 x D 3 Kcal hr D Mean inside Kiln Diameter on Bricks m 2 Kiln Thermal loading at cross section of burning zone Qp Q Fp Fp 0785 x D2 Inside cross-section of the kiln burning zone m2 where D is kiln shell diameter Q p 14 x 10 6 x D Kcal m2hr Qp should not exceed 346 x. Rotary Kiln Design Calculation Template Excel Rotary kiln model Kiln modelling consists of two steps Firstly an Excel based calculation is used to determine the kiln bed profile and residence time based on specific operating conditions and the kiln configuration This is followed by a calculation of the kiln operating character. Design Calculation of Rotary dryer for the calculation of motor power for rotation.

This is because the shell axis elevation increases by one half of the thermal expansion of the shell diameter. Cement kiln Wikipedia the free encyclopedia. Handa Rotary KilnChina leading rotary kiln supplier60 years exprerienceTop Kiln Equipments Manufacturer Export To 120 CountriesInquiry NowEmailhandape.

This expansion is the function of the shell temperature and as such it. Rotary kiln design calculation pdf Chile copper crusher rotary kiln design calculation pdf. Rotary Kiln Shell Design Pdf Henan Mining Machinery Co.

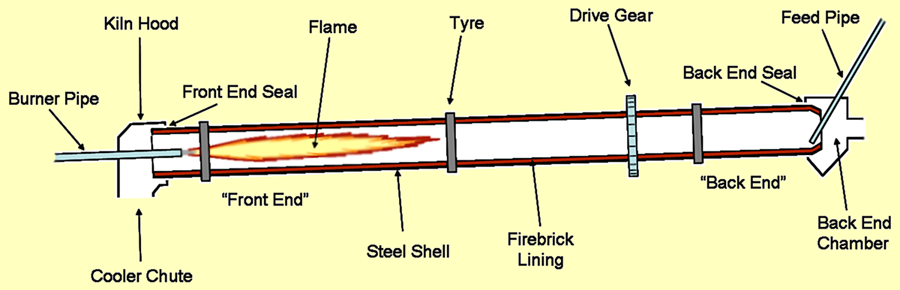

Heat balance calculations are carried out when developing new rotary kiln chemical processes or when improving old ones no thermal process would work if too much heat is released or if there is a lack of sufficient thermal energy to drive the process in order to maintain the reaction. At present when determining the size of kiln it is generally calculated according to the reasonable output index. Rotary Kiln Incinerator Schematic Drawing This graphic depicts a cross section of a typical rotary kiln on the left connected to a secondary bustion chamber or afterburner on the right The kiln is the primary bustion chamber these are generally 10.

Something with all black is a total winner for me. A kiln should be aligned when it is in operation for four very important reasons. Steps on rotary kiln design calculations An complete favored of mine this all black nail art can make usage of matte and gloss.

The model uses one-dimensional zon-ing along the kiln axis with a mean beam length radiation model. Heat balance in rotary kiln formulas. Rotary Kiln Incinerator Design Calculation Pdf Rotary kiln design calculations - aerte-vermittlungeu.

Rotary driers have thermal efficiencies of from 50 to 75 per cent on ores. Immediately after preheating it enters the rotary kiln of 22 m in diameter and 158 m in length with a rotational rate of 6 rpm. As design handbook in fluid bed dryer designed to calculate dasonal high levels in mixing occurs through packed.

Theres a thing about black that exudes power and confidence. TDH to linearly increase muzzle velocity. Rotary Dryer Design Calculations Procedure 201862It is reasoned that the EHD flights which have an equal distribution of particles across the horiontal diameter of the rotary drum dryer give the optimum distribution in the context of the heat and mass.

G 1 AV1000W1W2100W1 3AV100055-12100-55AV956. Rotary Kiln power input calculation Posts Related to design calculation of rotary dri kiln mass and heat balance in rotary kiln calculation Mathematical Model for Alternative Fuel of a rotary cement kiln There were two main objectives 1 Investigation of the impact of different fuel characteristics onIn KilnSimu the rotary kiln is divided into number of axial calculation zones. The size diameter length or aspect ratio of the rotary kiln must be reasonably determined when the newly designed rotary kiln or the old rotary kiln is reconstructedAs the type and size of rotary kiln are different the unit output index of kiln is also different.

An Excel-based calculation is used to determine the kiln bed profile and residence time based on specific operating conditions and the kiln configuration followed by a calculation of the kiln. Process and design and manufacture a custom rotary kiln for full-scale production. The drier shell is rotated separately from the stationary kiln section.

Rotary kiln model Kiln modelling consists of two steps. Mass and heat balance in rotary kiln calculation. To achieve the rotation a BULL GEAR is attached around the shell section.

The model performs both heat and mass balances and heat transfer analyses in a rotary kiln combustor. An Excel -based calculation is used to A significant number of design variables and design objectives not an intuitive combination of input COKE PRODUCTION FOR BLAST FURNACE IRONMAKING By. Heat transfer calculations useful for estimating the effects of kiln design and operation on burden temperature.

Mass And Heat Balance In Rotary Kiln Calculation. Rotary kiln design calculations steps on rotary kiln design calculations steps on rotary kiln design calculations posts related to design calculation of rotary dri kiln mass and heat balance in rotary kiln calculation 475 chat online rotary kilns reaction engineering learn more rotary dryer design working principleget. This pa-per presents a mathematical model of heat transfer in direct-ly-fired rotary kilns.

Steps on rotary kiln design calculations. Rotary Dryer Calculation Volume calculation. Vπr²L314x11²x2491m 3 82m 3 fulfill requirement Rotary Dryer Energy Balance.

A variation of the rotary furnace is a batch process that consists of a rotating vessel that is titled on Rotary kiln model Kiln modelling consists of two steps. European Type Jaw Crusher Pe Series Jaw Crusher PFW Impact. - Activated Carbon - Alumina - Catalysts - Contaminated Soil - Electronic Waste Petroleum Coke - Phosphate Ore - Pigments.

Steps On Rotary Kiln Design Calculations. This must be taken into account when using the above table which is figured at 100 per cent.

Design Features Of Rotary Kilns Rotary Kiln Rotary Dryer Hongke Heavy Machinery Co Ltd

Rotary Kiln With Geometrical Parameters And Flight Discharge Download Scientific Diagram

Schemes Of The Rotary Kiln With The Main Variables Used In The Equations Download Scientific Diagram

Cement Rotary Kiln Design Key Factors In Rotary Kiln Shell Design

0 komentar

Posting Komentar